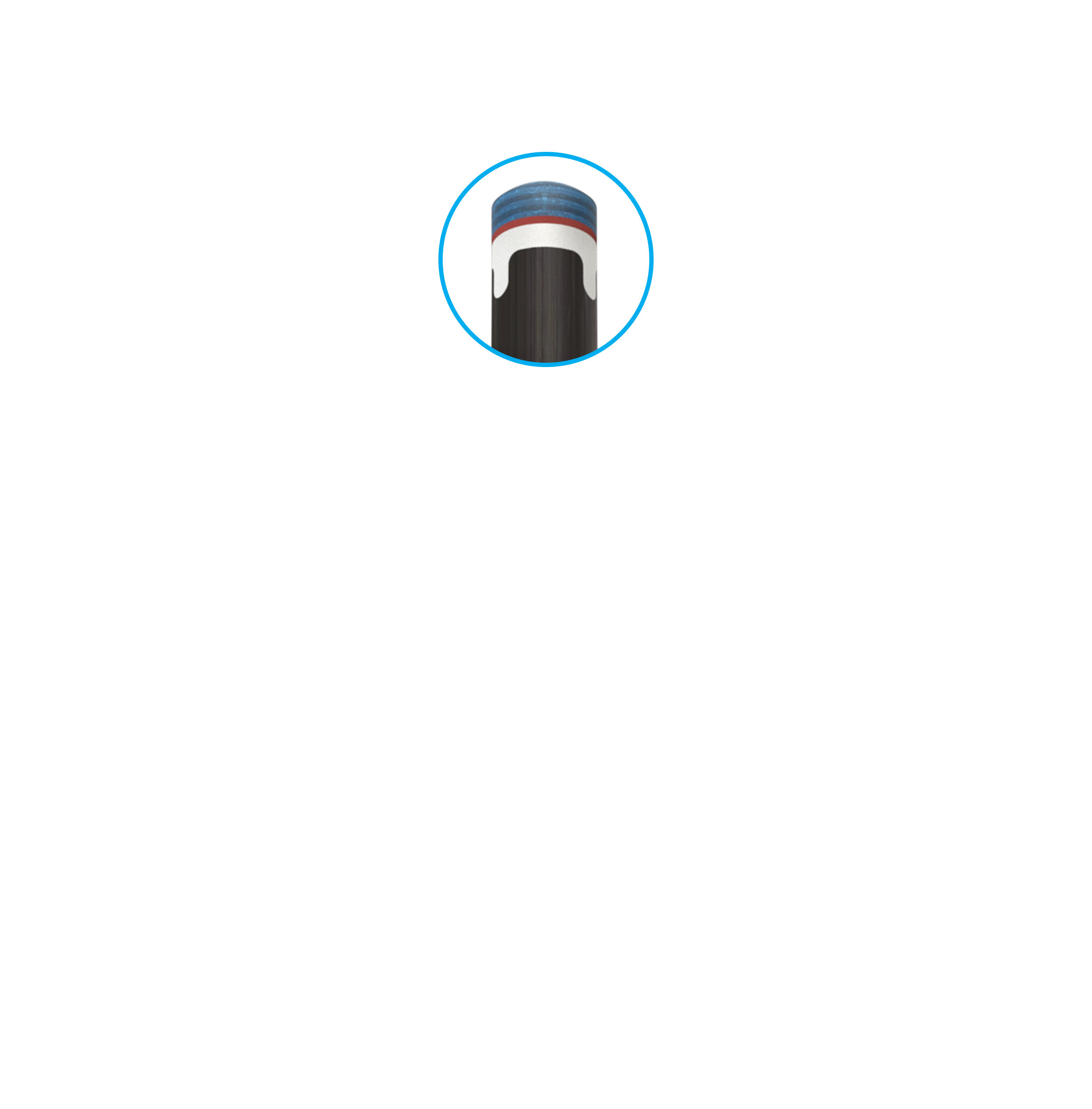

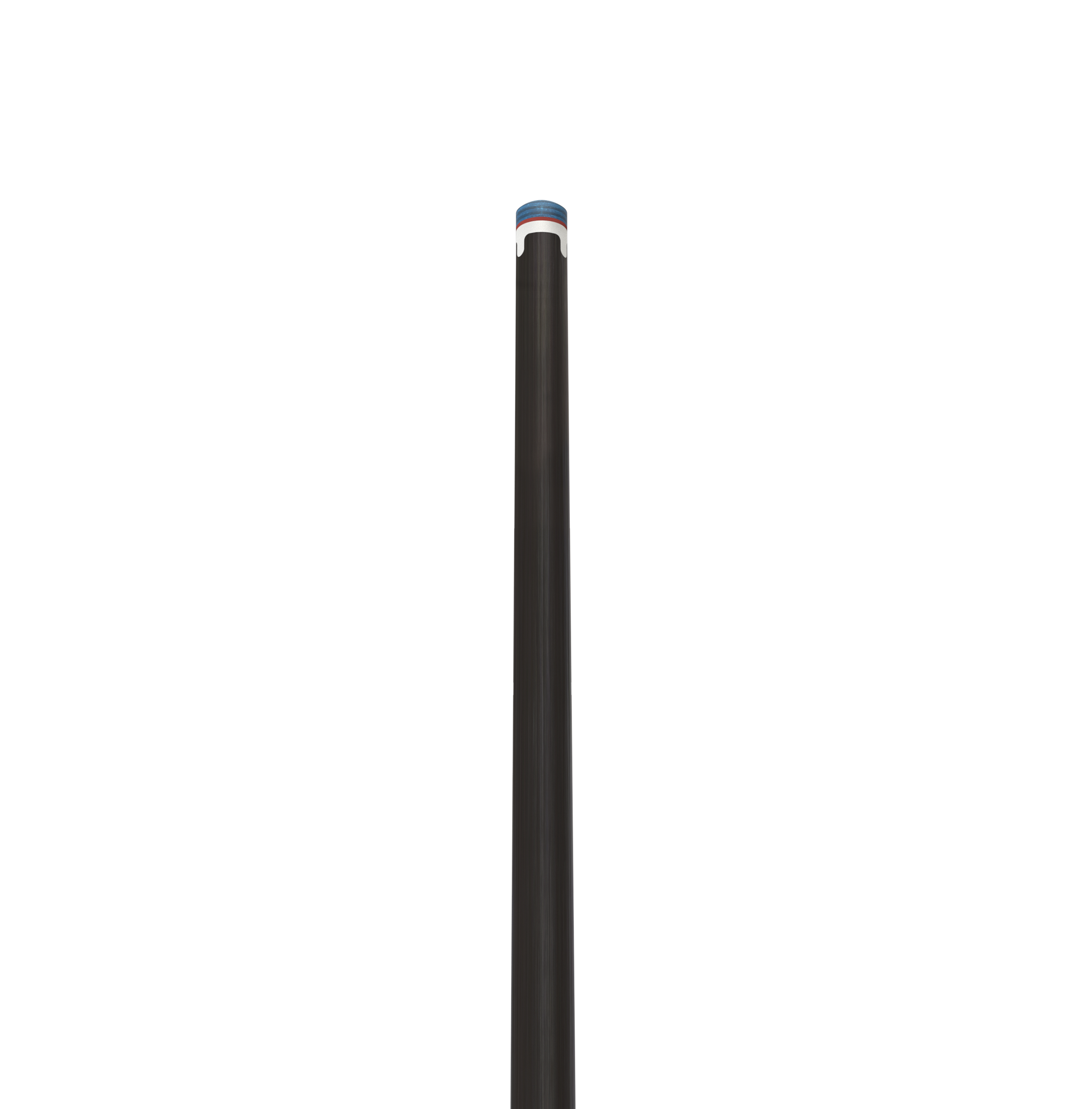

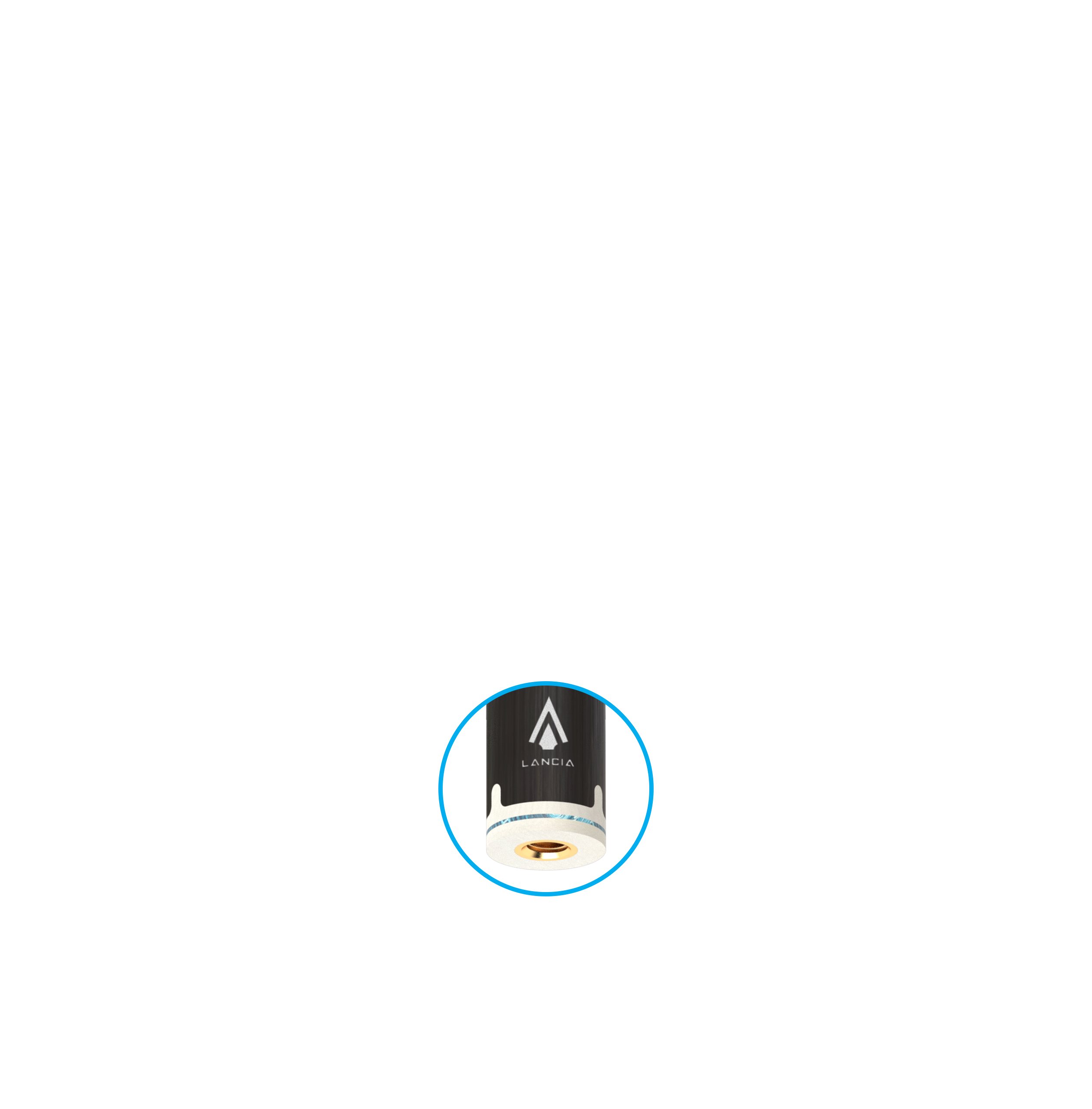

ferrule design

1 This ferrule ensures a better distribution of the forces endured during hard shots with maximum spin. It provides for a larger contact-surface with the shaft-body and results in perfect feedback in all conditions. Each ferrule is machined from G10 on a specialty CNC-center, guaranteeing a very high accuracy and the tightest possible fit for maximum reliability.

2 A Kevlar pad is fitted between the ferrule and the tip as tip-support. This helps to evenly distribute the impact-forces over the entire surface of the Trident® ferrule and dampens the vibrations transferred to the shaft-body.

3 The lightweight construction allows for shafts with very low deflection properties but at the same time retaining the necessary strength and stability.

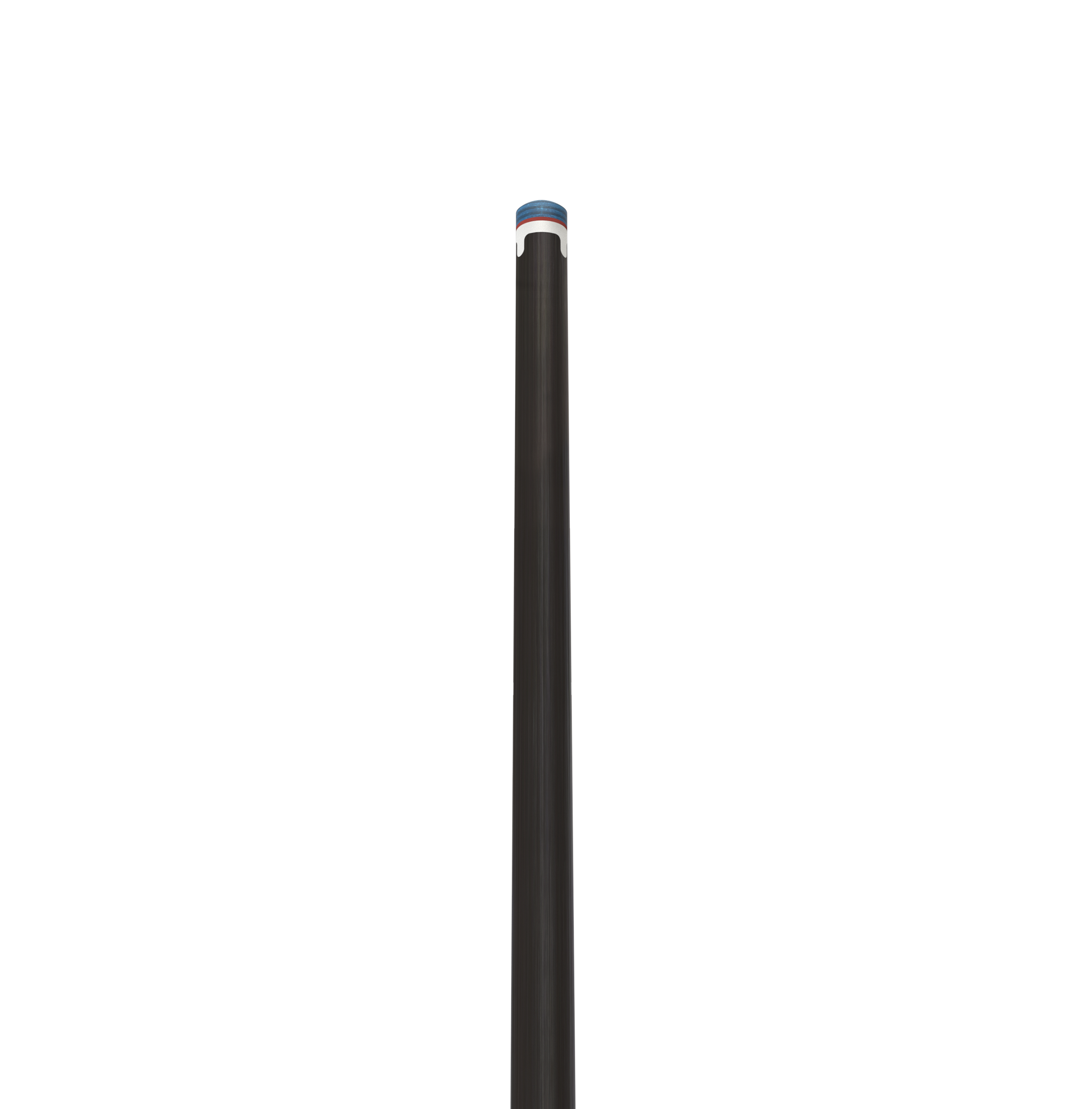

Shaft body

4 Whereas most composite shafts are manufactured by wrapping “Prepreg” sheets of composite fibers over a steel core and finishing the outside of the tube by sanding, we noted this technique resulted in a too wide variation in “wall thickness” and consequently uneven radial consistency. A new technique was developed resulting in a wall-thickness variation limited to +/- 0,1 mm over the full length of the shaft-body: guaranteeing 100% radial consistency.

5 Our in-house production technique allows for an infinite variation of shapes and materials; we are able to build shafts exactly to any players’ requirements.

Collar design

6 We offer three stunning ring colors — cyan, magma dragon, and black — according to your preferences.

joint system

7 We equip your shaft with the most reliable joint system out there: Radial.

FERRULE DESIGN

This ferrule ensures a better distribution of the forces endured during hard shots with maximum spin. It provides for a larger contact-surface with the shaft-body and results in perfect feedback in all conditions.

Each ferrule is machined from G10 on a specialty CNC-center, guaranteeing a very high accuracy and the tightest possible fit for maximum reliability.

A Kevlar pad is fitted between the ferrule and the tip as tip-support. This helps to evenly distribute the impact-forces over the entire surface of the Trident® ferrule and dampens the vibrations transferred to the shaft-body.

The lightweight construction allows for shafts with very low-deflection properties but at the same time retaining the necessary strength and stability.

SHAFT BODY

Our in-house production technique allows for an infinite variation of shapes, wall thicknesses, and materials; we are able to build shafts exactly to any players’ requirements.

COLLAR DESIGN

We offer three stunning ring colors — cyan, magma dragon, and black — according to your preferences.

JOINT SYSTEM

We equip your shaft with one of the most widely used joint systems: Uni-loc® or Radial, ensuring reliability.