Butt – collar

1

The central part of the butt-collar consists of a single piece of linen-based Phenolic Resin which holds the Monolith® joint pin and ensures the lossless transmission of energy towards the shaft without initiating any unwanted vibrations. All structural parts are not only glued but also threaded for a tighter fit and durability.

Body

2A multi-layer design with carefully selected composite fibers is fused into a single part and was engineered with the focus on eliminating unwanted vibrations and maximized energy-transfer.

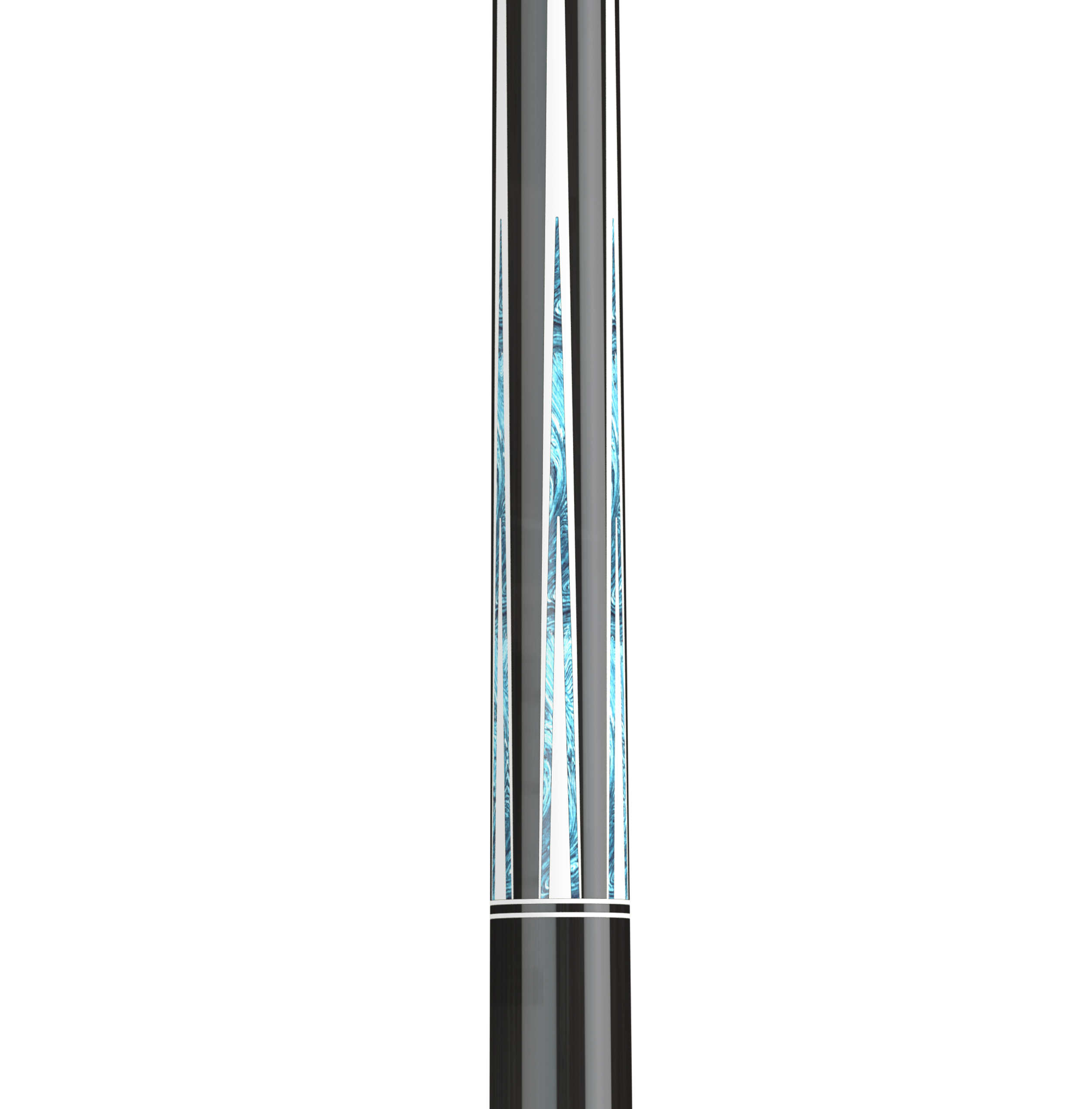

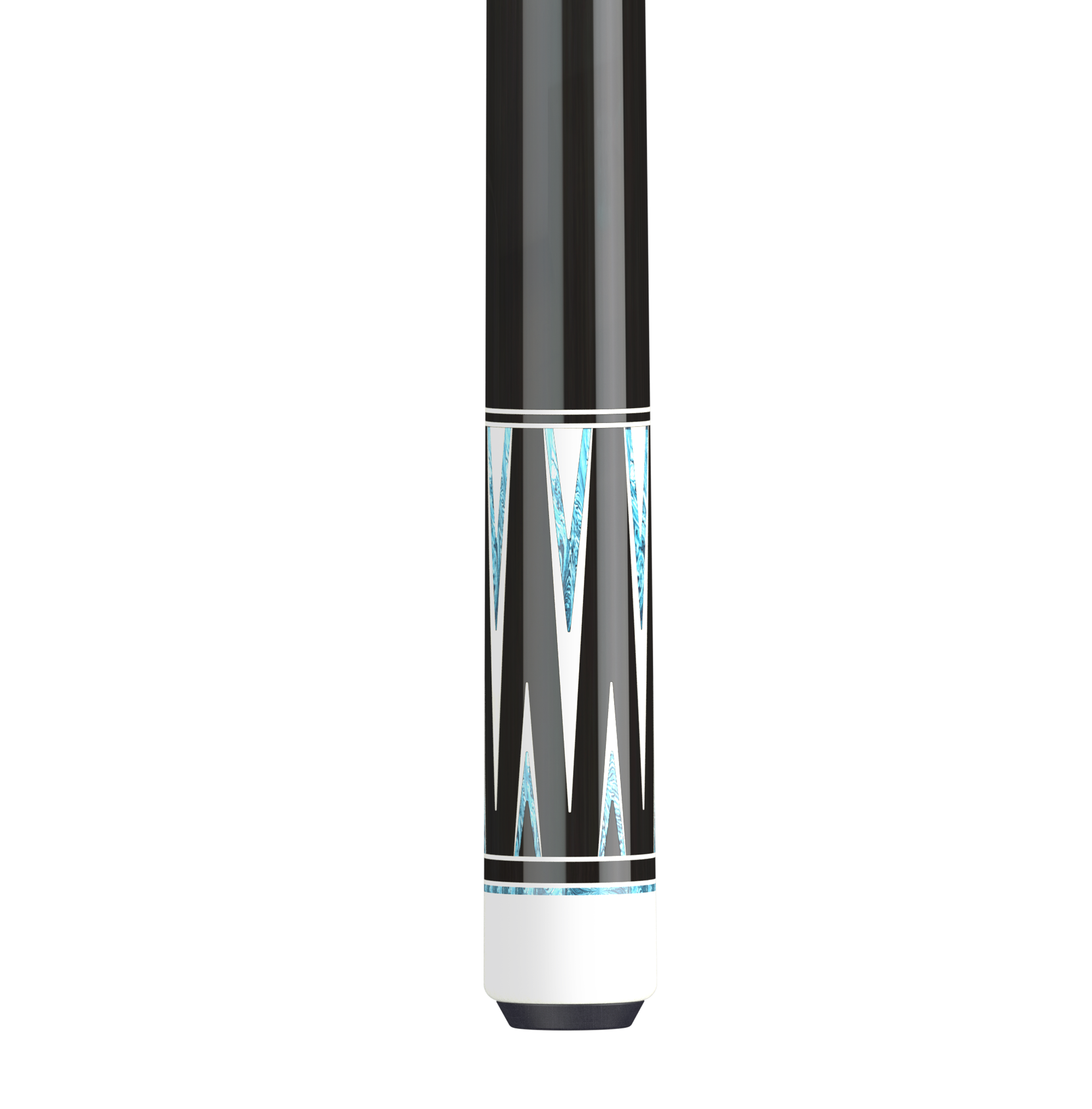

What you see is what you get!

Molinari refrains from using inferior techniques for the optical aspects of our products, like there are decals, “on-lays” or prints. Every design feature is a real inlay just as used in traditional high-end cue manufacturing.

Molinari® is proud to be the first cue manufacturer having re-engineered the inlay technique into a workable solution for use in dense composite structures.

The spindles on our CNC-centers rev up to 65.000 rpm, we use end mills with a diameter of less than 0,004 “ controlled by an automated measuring system. The A-axis have a position – repeatability of better than 1/100 of a degree and the X-Y-Z axis’s have a positioning – accuracy better than 0,005 mm/meter.

The cavity within the shaft-body is filled with a low density foam as an additional damper to counteract unwanted vibrations.

Grip

3Many models are available with leather or linen grips. For grips for carom games, please refer to our accessory section.

Adjustable weight

4A weight-cartridge has been integrated in the back of the handle allowing for quick and effortless changes to the weight of your cue. The inside lining of the cartridge is especially designed to “hold” the weights in the correct position.

BUTT - COLLAR

The central part of the butt-collar consists of a single piece of linen-based Phenolic Resin which holds the Monolith® joint-pin and ensures the loss-less transmission of energy towards the shaft without initiating any unwanted vibrations. All structural parts are not only glued but also threaded for a tighter fit and durability.

BODY

A multi-layer design with carefully selected composite fibers is fused into a single part and was engineered with the focus on eliminating unwanted vibrations and maximized energy-transfer.

What you see is what you get!

Molinari refrains from using inferior techniques for the optical aspects of our products, like there are decals, “on-lays” or prints. Every design-feature is a real inlay just as used in traditional high-end cue-manufacturing. Molinari is proud to be the first cue-manufacturer having re-engineered the inlay technique into a workable solution for use in dense composite structures.

The spindles on our CNC – centers rev up to 65.000 rpm, we use end mills with a diameter of less than 0,004 “ controlled by an automated measuring-system. The A-axis have a position – repeatability of better than 1/100 of a degree and the X-Y-Z axis’s have a positioning – accuracy better than 0,005 mm/meter.

The cavity within the shaft-body is filled with a low-density foam as an additional damper to counteract unwanted vibrations.

What you see is what you get!

Molinari refrains from using inferior techniques for the optical aspects of our products, like there are decals, “on-lays” or prints. Every design-feature is a real inlay just as used in traditional high-end cue-manufacturing. Molinari is proud to be the first cue-manufacturer having re-engineered the inlay technique into a workable solution for use in dense composite structures.

The spindles on our CNC – centers rev up to 65.000 rpm, we use end mills with a diameter of less than 0,004 “ controlled by an automated measuring-system. The A-axis have a position – repeatability of better than 1/100 of a degree and the X-Y-Z axis’s have a positioning – accuracy better than 0,005 mm/meter.

The cavity within the shaft-body is filled with a low-density foam as an additional damper to counteract unwanted vibrations.

GRIP

Many models are available with leather or linen grips; check the availability on our configurator. For grips for carom games, please refer to our accessory-section.

ADJUSTABLE WEIGHT

A weight-cartridge has been integrated in the back of the handle allowing for quick and effortless changes to the weight of your cue. The inside lining of the cartridge is especially designed to “hold” the weights in the correct position.